Video Borescope

Things You Might Not Know About Industrial Borescopes

Industrial borescopes are indispensable devices for inspecting, maintaining, and repairing modern machinery. This article will help you discover fascinating facts about industrial borescopes: how they work, their practical applications across various industries such as manufacturing, automotive, aerospace, electronics, and the outstanding benefits these devices offer.

I. What Is an Industrial Borescope? Basic Knowledge You Should Know

1.1 Definition of Industrial Borescope

An industrial borescope is a specialized device used to inspect and observe hard-to-reach areas inside machines, equipment, and pipelines without disassembling them. This device usually consists of a flexible or rigid tube, a camera, and a light source, allowing real-time image transmission to a display screen.

1.2 Basic Operating Principle

Industrial borescopes operate on the principle of transmitting images from a probe camera through a cable to a display screen. Thanks to high-resolution cameras and LED lighting, images inside machine components are magnified and clear, helping detect defects, cracks, foreign objects, or wear.

1.3 Common Types of Industrial Borescopes

Rigid borescopes: Used for straight, non-bending areas.

Flexible borescopes: Flexible and easy to maneuver into complex locations.

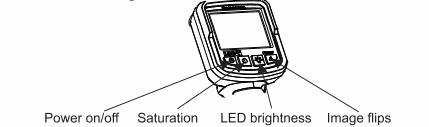

Video borescopes: Integrated with a camera, display screen, and image/video storage.

Related Articles:

Images from UNI-T industrial endoscopes become blurred after a period of use? What is the cause?

Tips for the most accurate calibration of industrial endoscopes

II. Practical Applications of Industrial Borescopes

2.1 Inspection, Maintenance, and Repair of Machinery

Industrial borescopes are essential tools in industrial machinery maintenance and repair, helping detect early technical faults and wear inside engines, gearboxes, compressors, minimizing the risk of major failures. In manufacturing plants, engineers use industrial borescopes to inspect gears inside gearboxes, timely detecting small cracks before serious problems occur.

2.2 Real-World Use in the Automotive Industry

In the automotive sector, industrial borescopes help inspect cylinders, pistons, valves, and exhaust systems without dismantling the engine. This saves time, cost, and ensures maintenance quality. When a vehicle shows reduced power, technicians use industrial borescopes to check cylinders, detect heavy carbon deposits, and propose appropriate cleaning solutions.

2.3 Inspecting Welds and Joints in Manufacturing

Industrial borescopes assist in checking weld quality, detecting cracks, air bubbles, or technical defects invisible to the naked eye. This is a critical step in steel structure manufacturing, pressure vessel fabrication, and oil & gas pipeline production.

2.4 Applications in Aerospace, Electronics, and Construction

Aerospace: Inspect turbine blades, jet engines, detect cracks and foreign objects, ensuring flight safety.

Electronics: Inspect printed circuit boards, detect soldering defects and oxidized joints.

Construction: Inspect electrical systems, concealed water pipes, locate leaks or blockages.

III. Outstanding Benefits of Industrial Borescopes

3.1 Saving Time and Costs

Industrial borescopes reduce disassembly and inspection time, while lowering maintenance and repair costs by detecting technical faults early. For example, a manufacturing plant uses industrial borescopes for periodic compressor system checks, detecting oil leaks early to avoid full equipment replacement.

3.2 Enhancing Inspection Quality and Ensuring Safety

With sharp images and the ability to access hard-to-reach areas, industrial borescopes enable detailed inspections, detecting even the smallest defects, thereby ensuring product quality and operational safety.

Example: In pressure vessel weld inspections, industrial borescopes detect tiny air bubbles, preventing potential vessel explosions.

3.3 Versatile Applications and Easy to Use

Industrial borescopes come in diverse types suitable for various industries, with simple operation accessible even to beginners. Residential electricians can use industrial borescopes to inspect concealed wiring, quickly locating breaks without wall demolition.

IV. Diverse Industrial Borescope Brands at EMIN

If you are looking for high-quality industrial borescopes with diverse models suitable for many industries, EMIN is a reliable destination. EMIN offers industrial borescopes from reputable brands, meeting all your inspection and maintenance needs. Their professional consulting team and attentive after-sales service will help you choose the most suitable product.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-